Project Overview

Simply put, the todos productivity board is an organization tool designed specifically to help those who struggle with executive dysfunction maintain better control in their day‑to‑day life. A familiar whiteboard with an attached robotic dry-erase marker, this device reimagines task management and goal tracking, providing a new path towards structure that removes the distractions inherent in digital systems and lessens the energy costs associated with maintaining paper planners.

Throughout the day, todos translates your digital to‑do lists and goals onto its surface, keeping you focused and organized. Users simply place magnets on the board to interact, triggering sensors that record task completion, as well as other metrics such as mood and self-assessments of productivity and sleep. Wifi connection allows for up-to-date information, like weather forecasts, to help users plan their day. With Bluetooth configuration via a custom web portal, the system can be easily customized to adapt perfectly to your workflow and goals.

In addition to all of this, a core goal of this project was to create a platform for communication and interaction that can adapt well to environments and use cases of many kinds. A whiteboard is, quite literally, a blank slate. A robotic marker is a versatile communicator and the placement of magnets on a board is a fairly accessible user input system.

Below, find the demo video for todos.

Why This Matters

Responsibilities like keeping a consistent morning routine, remembering an upcoming event or commitment, or even keeping personal long-term goals front of mind (to name just a few) are often made difficult or impossible by executive dysfunction. The consequences of an individual lapse in attention may seem relatively small, but bills not paid, friends not spoken to and showers not taken, for example, can quickly add up to something more overwhelming.

Most of our discussion about executive function, while working on this project, has focused on people who suffer from Attention Deficit/Hyperactivity Disorder (ADHD,) but it is important to acknowledge that many other conditions and diagnoses have been linked to executive dysfunction; Alzheimer's disease, epilepsy, head injury and substance abuse are just a few examples.

Many available tools can take a lot of focus and energy to keep up with. A written planner, for example, can only serve as a reminder if the user continually remembers to populate it with new information. Other popular tools use digital push notifications to alert the user, but these can often be tuned out in favor of more immediately-rewarding activities, like scrolling through social media feeds.

The Team

This project served as the Senior Capstone Project for my degree in Creative Technology and Design at the University of Colorado, Boulder. My teammates, Jason Fontillas and Sydney Calcagno, and I worked together to transform this vision into a reality.

Project Breakdown

At a glance...

The work that went into this project can primarily be broken down into four main categories: hardware, circuitry, software and user experience. My contributions were primarily in the hardware, circuitry and software components; however, I felt like I added a lot to the project in all areas. After all, it is difficult to separate these three categories in practice when everything must work together seemlessly in the final product.

Hardware

At the core of this build (besides the whiteboard itself) is a 2-axis Computer Numerical Control (CNC) plotter. CNC devices allow for precise control over motion; in this case, we are moving a dry-erase marker on two axes. For this sort of construction, I turned towards a brand I'm familiar with from some previous projects, Openbuilds. Openbuilds has a modular system of parts that works well for designing these sorts of CNC machines; with aluminum extrusions, mounting hardware and linear actuator systems that are all compatible with one another, it was easy to prototype the plotter mechanism. Below is a video of some early testing of the linear actuators.

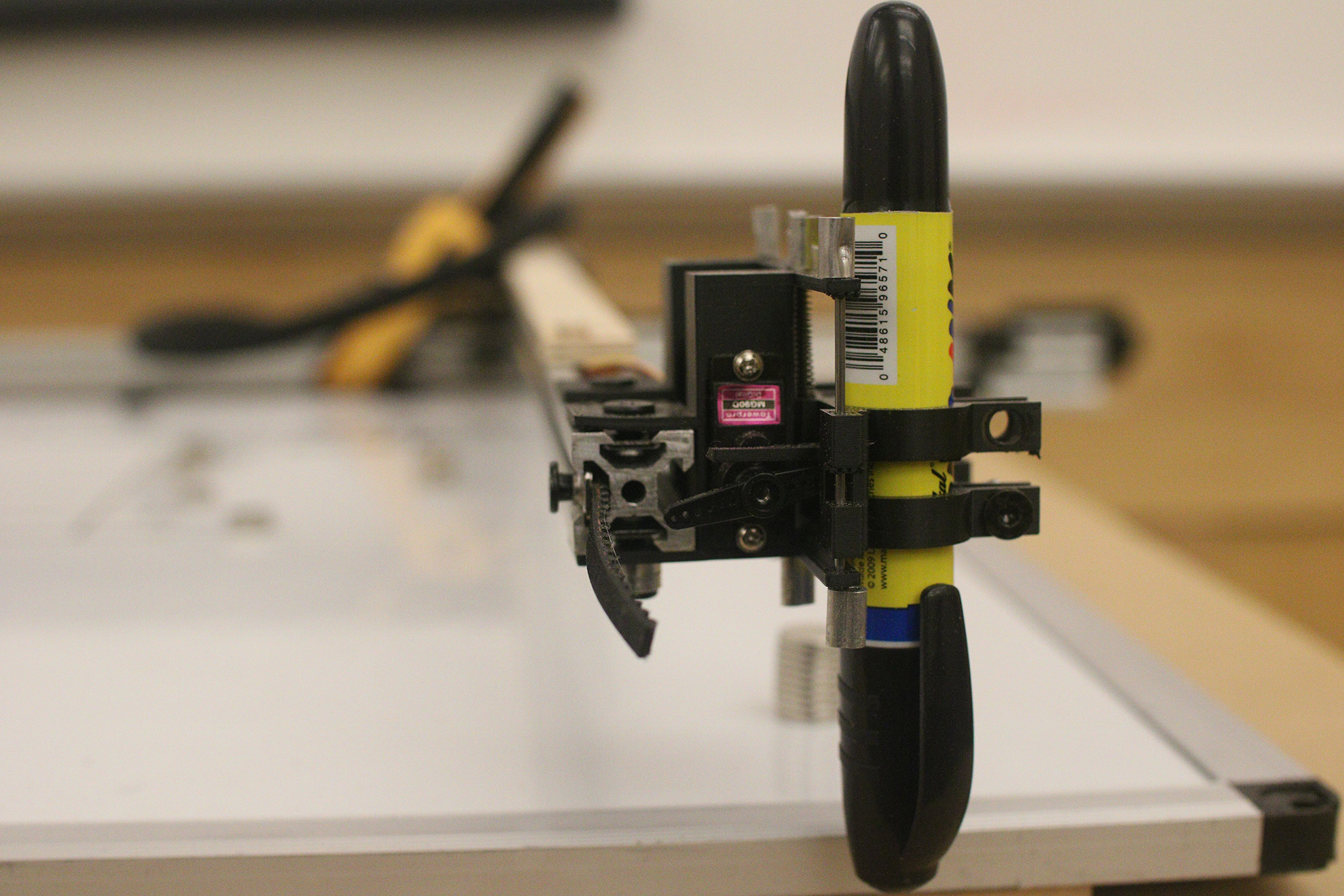

Quite a few other parts required more unique designs, so I opted to design and fabricate custom components to fill those gaps. Shown below are a few examples that I 3D printed; on the left is a servo-powered pen lift mechanism, and on the right is an example of a limit switch mount. Additionally, all of the mounts for the electronics, as well as some other brackets, were printed for the project.

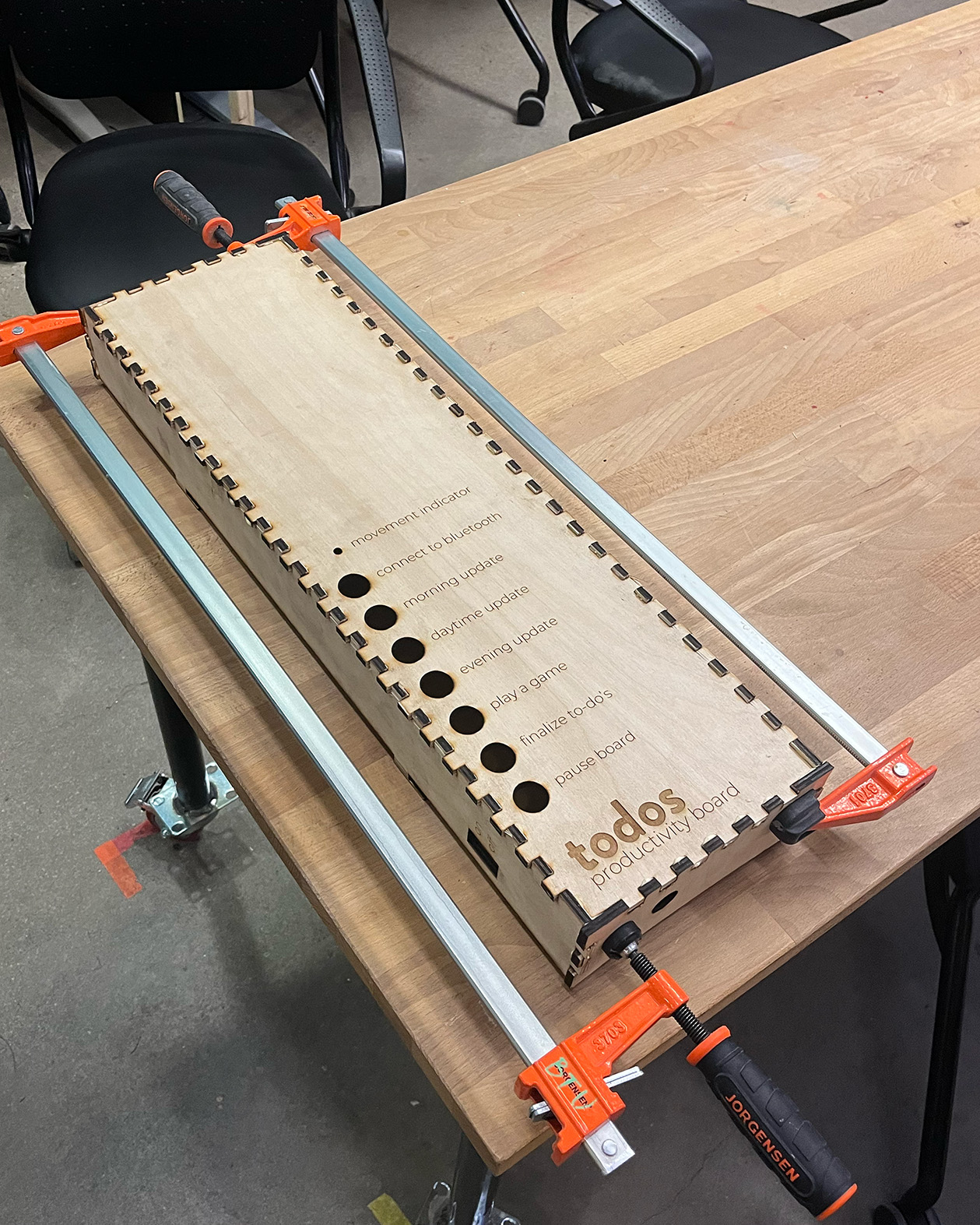

A final component of the build that improved the overall presentation of the project was the enclosure I fabricated. We understood from the start that the aesthetic of todos should be well-suited for an average home.

Despite our pride in our electronics, it was best to hide them. A simple laser-cut box was the easiest solution, but I did my best to make it look presentable; I sanded down burnt edges and tried to be precise, even though this was my first attempt at making an enclosure like this.

Circuitry

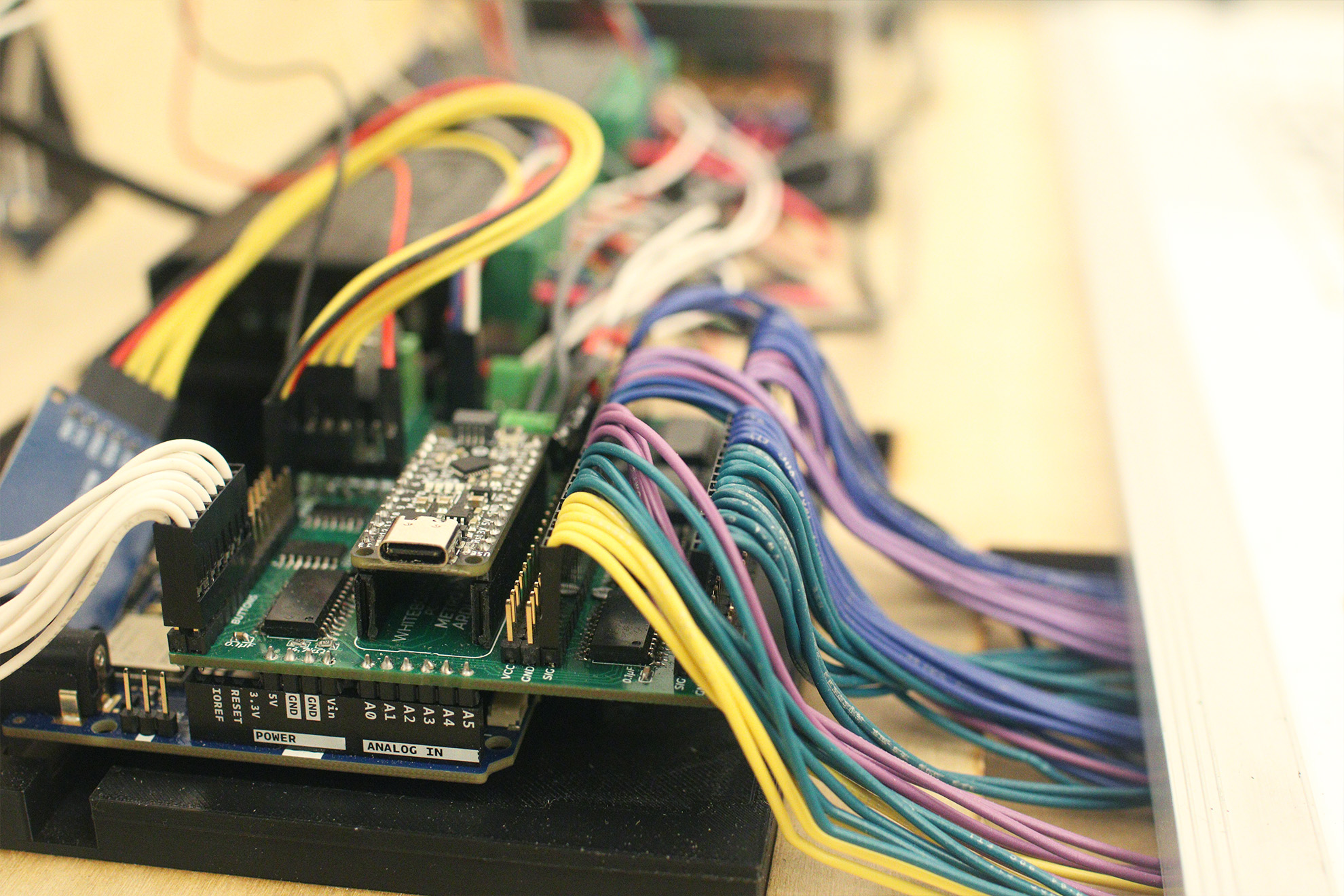

The challenge of designing a circuit that could execute all of our initial ideas for the build while maintaining the ability to adapt to later changes was an exciting one. This was not too straightforward, and I had opted to challenge myself to create a printed circuit board (PCB) design to make the final product more elegant. This was my first foray into this sort of design process and I'm happy with what it yielded:

The green circuit board shown above is my own design. I have plans to create a full walkthrough of the circuitry eventually, but I'll give a brief rundown in the meantime. To generate the movement we needed from the plotter, we have two stepper motors (one each for the x and y axes.) Additionally, there is a servo motor to lift and lower the marker (and another for a theoretical eraser.) We used one microcontroller to process motion commands and send signals to those motors, and another microcontroller to act as the "brain" of todos, which sends commands to the first. Add in a microSD card reader for storing data, seven buttons on the front panel and 57 magnet sensors on the back and a potential wiring disaster starts to form.

That leaves out quite a few details, but the justification for the custom PCB becomes clear when working on a system with so many moving parts and required connections. We didn't run into many hiccups or unforeseen difficulties with the circuitry... I am not so naive to think that my skill had anything to do with it, but I did as much research as I could in planning the design and we got lucky!

Software

For this project, the vast majority of my effort was put into developing the software. The circuitry related to the motion of the CNC machine was relatively straightforward, and we used a slightly-modified version of a library called GRBL to translate our somewhat-understandable motion commands into signals the motors could use. At that point, we were still left with a quite-useless jumble of aluminum and wires. The microcontroller that I mentioned was the "brain" of the operation wasn't doing any thinking on its own.

The foundation of todos was in place, and Sydney, Jason and I set out to make it something useful and usable. From creating a framework with which to convert text into cartesian motion, to creating the protocol with which to send information over bluetooth to our custom web portal.... From turning the placement of magnets on the whiteboard's surface into meaningful information, to programming a reward system that helps users stay motivated to work towards their goals. There is a lot that we brought to life in todos. There is much more that we have yet to implement, too.